What is Machine Vision?

Machine vision is a transformative technological domain that intersects automation, digital imaging, and artificial intelligence. It enables machines and computer systems to perceive their surroundings, analyze visual data, and make decisions based on the visual information they obtain. The applications of machine vision extend across various sectors, significantly enhancing productivity, quality control, and operational safety in industries from manufacturing to healthcare.

Definition and Core Concepts

At its core, machine vision involves the use of one or more imaging devices to capture images, followed by the processing of these images through sophisticated algorithms. The objective is to autonomously analyze the visual data to make informed decisions or provide feedback in real-time. The technology encompasses a wide range of methods, including image processing, pattern recognition, and the integration of artificial intelligence, to facilitate automated inspections and analyses. Various industries employ machine vision for distinct purposes, such as enhancing production quality and ensuring safety standards are met.

Components of Machine Vision Systems

A typical machine vision system consists of several critical components:

- Cameras: These are the eyes of the system, capturing images. The choice of camera (2D, 3D, or multispectral) is often dictated by the specific application.

- Lighting: Adequate and specialized lighting conditions are integral to ensure high image quality. Different tasks may require specific light types (e.g., LED, laser) to reduce shadows and enhance contrast.

- Processing Software: This software analyzes the images and extracts relevant information using various algorithms. It performs tasks such as object detection, measurement, and defect analysis.

- Communication Interfaces: These allow the machine vision system to relay its findings to other systems (like robots or production lines) for further action.

- Mounting and Frame Structures: These support the cameras and lighting setups, ensuring they are maintained at the correct angles and distances from the objects being inspected.

Principles Behind Machine Vision Technology

The principles guiding machine vision technology are rooted in the combination of optics, imaging, and computer science. Machine vision systems process images through several steps:

- Image Acquisition: Captured images are digitized for processing.

- Pre-Processing: Images are enhanced to improve quality through techniques like filtering and binarization.

- Feature Extraction: Important features are identified within the image, which may involve edge detection, contour following, or pattern recognition.

- Decision Making: The system employs predefined criteria or machine learning models to analyze features and determine actions or quality assessments.

The Advantages of Machine Vision in Industry

Machine vision technologies bring numerous benefits to industrial environments, enhancing operational efficiency and product quality. Understanding these advantages can help organizations unlock their full potential.

Enhancing Product Quality and Consistency

The application of machine vision in quality control processes allows for precise inspection of products, ensuring they meet specified standards. By utilizing consistent image capture and analysis techniques, machine vision systems reduce human error and variability in inspections. The ability to detect defects, such as surface blemishes or incorrect assembly, in real-time prevents subpar products from proceeding down the production line.

Cost-Effectiveness in Automated Processes

Implementing machine vision technology can lead to substantial cost savings for companies. By automating visual inspections, organizations minimize the need for manual labor in quality control, allowing workers to focus on higher-value tasks. Additionally, early detection of defects translates to lower costs associated with recalls, returns, or rework.

Improving Safety and Reducing Errors

Machine vision systems contribute to improved workplace safety by overseeing hazardous processes and ensuring that operations adhere to safety protocols. Moreover, the reduction of human involvement in high-risk environments decreases the likelihood of accidents. With fewer errors during inspections and operations, companies can enjoy smoother workflows and reduced operational interruptions.

Common Applications of Machine Vision

Machine vision applications are diverse and can be found across various industries. The ability to analyze images and extract useful data has made it an integral component of many automated systems.

Quality Control and Defect Detection

One of the most common applications of machine vision is in quality assurance processes. Machine vision systems can rapidly assess products for defects such as scratches, dents, or incorrect dimensions. They often use sophisticated algorithms to analyze defects against specified tolerances, ensuring manufacturing consistency and high standards. The automation of these processes means rapid throughput and the ability to inspect products at speeds far exceeding human capabilities.

Barcode Reading and Identification

Another critical application is in barcode reading, which is essential for inventory management and logistics. Machine vision systems are utilized to capture, process, and interpret barcodes on products at high speeds, ensuring seamless tracking and sorting within warehouses or production lines. The implementation of machine vision for barcode reading leads to increased accuracy, reduced mislabels, and better inventory control.

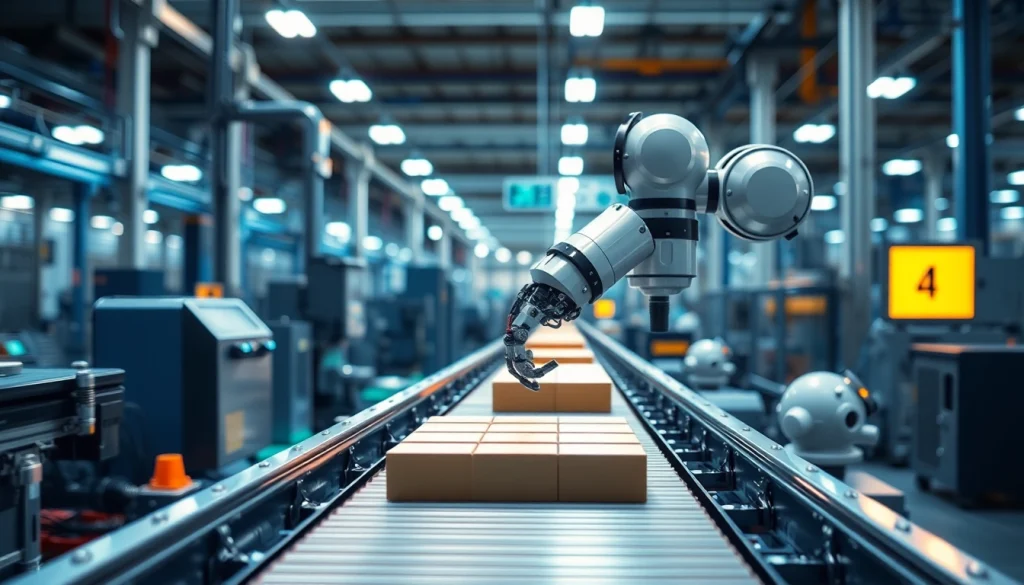

Guidance in Robotic Automation

In the realm of robotics, machine vision serves as a guiding mechanism that provides robots with the ability to recognize, locate, and interact with objects in their environment. This capability is vital in settings such as automated manufacturing, where robots need precise details about the positioning of items to perform tasks like picking and placing. By utilizing machine vision, robotic systems can adapt to changes in their environment, enhancing flexibility and efficiency.

Machine Vision vs. Computer Vision: Key Differences

While machine vision and computer vision are related fields, they are characterized by distinct purposes and applications. Understanding these differences is essential for businesses considering the integration of such technologies.

Defining Each Technology

Machine vision primarily focuses on automating visual inspection tasks within industrial processes. Its purpose is to enhance quality control, operational efficiency, and safety. On the other hand, computer vision encompasses a broader scope, including the interpretation of visual data for applications such as facial recognition, autonomous vehicles, and medical imaging. In essence, while all machine vision systems can be classified under computer vision, not all computer vision applications are considered machine vision.

Applications in Different Industries

The applications of each technology reflect these differences. For instance, machine vision is predominantly implemented in manufacturing and logistics for tasks like assembly verification and inventory scanning. Conversely, computer vision finds utilization in sectors like healthcare for diagnostic imaging and in automotive industries for self-driving technology.

Technological Overlaps and Distinctions

Despite their differences, there are significant overlaps. Both technologies utilize similar foundational techniques involving image processing algorithms, though machine vision is typically more focused on specific pre-defined tasks. Technologies such as neural networks and deep learning can be seen in both fields, yet machine vision systems favor application-specific solutions designed for standardization.

Implementing Machine Vision in Your Operations

For organizations looking to adopt machine vision systems, a systematic approach is essential for successful implementation. This includes selecting the appropriate system and evaluating its performance.

Choosing the Right System for Your Needs

When selecting a machine vision system, organizations should assess their unique requirements, such as the types of products to be inspected, the operating environment, and the inspection speed needed. Collaborating with experts can aid in identifying compatible cameras, lighting, and software solutions tailored to those needs. Moreover, it’s vital to ensure that the system can integrate smoothly with existing processes and equipment.

Performance Metrics and Evaluation

Measuring the effectiveness of a machine vision system involves tracking various performance metrics including accuracy, throughput, and failure rates. Organizations must establish baseline performance levels before implementation and continually monitor the system’s results post-deployment. This can lead to timely optimizations in the system’s configuration or the training of personnel on best practices for maximizing its effectiveness.

Case Studies and Success Stories

Numerous companies have successfully integrated machine vision into their operations, showcasing its potential. For example, a leading automobile manufacturer incorporated a machine vision system to inspect welding seams, enhancing both speed and quality levels of production. Similarly, a major food processing company adopted machine vision for its packaging lines, resulting in a significant decrease in incorrectly packaged goods.

These real-world examples highlight the tangible benefits machine vision technology can provide when implemented correctly.